High-Pressure Laminate (HPL) Panels

High-Pressure Laminate Panels (HPL) revolutionize architectural panels and cladding with their captivating aesthetics and boundless design potential. Discover a world of endless creativity while relishing in the assurance of lasting durability without compromising visual appeal! Renowned as one of the most adaptable wall panel systems, high-pressure laminates offer effortless maintenance and are tailored for high-traffic environments.

To delve deeper into the world of HPL panels, continue reading below or browse through our project portfolio for inspiration. We invite you to reach out today so we can discuss your vision and provide a customized bid tailored to your needs.

Developed from plastic laminate, HPL panels are great for fire, chemical, and wear resistance. But how are high-pressure laminate panels manufactured?

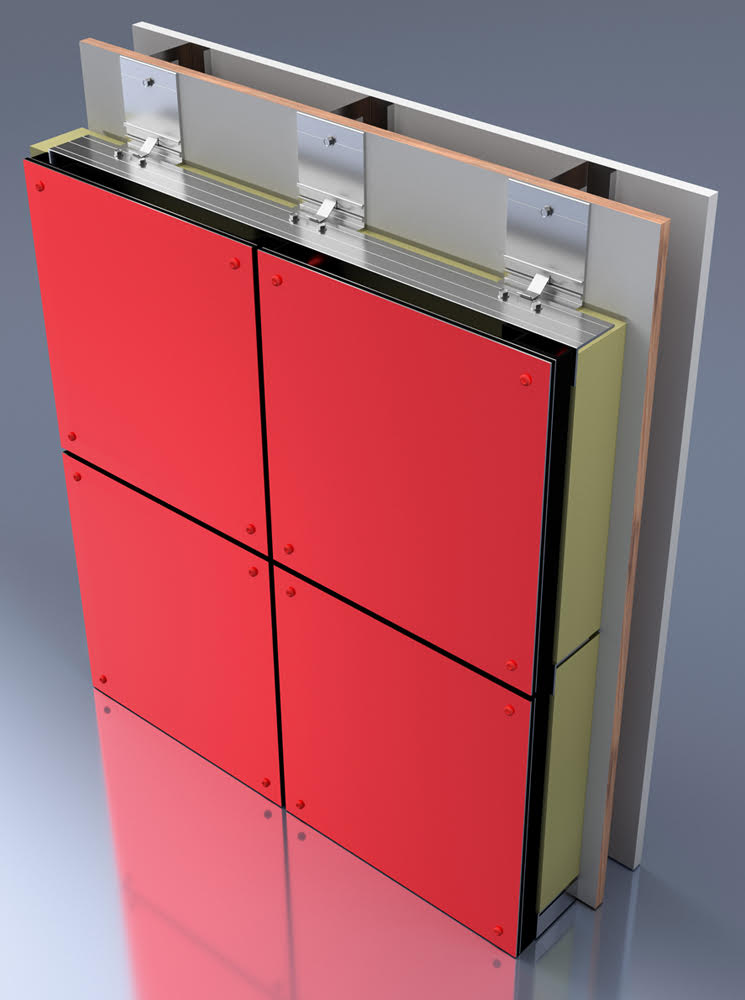

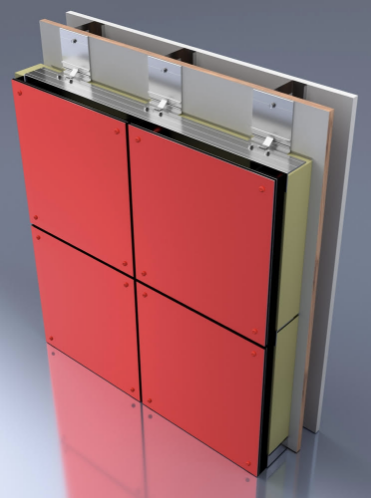

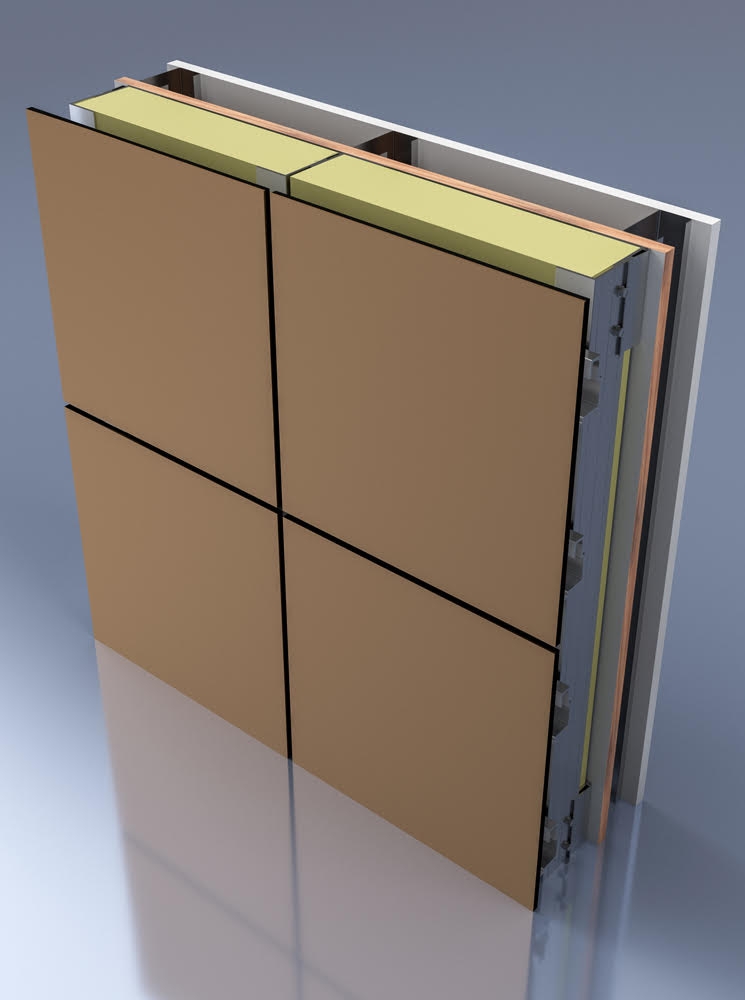

First, high-pressure laminate sheets are applied to panels with PVC glue adhesives. Multiple layers of Kraft paper are covered in phenolic resin. Next, a layer of decorative d©cor paper is placed on top and fused via high PSI heat and pressure. This curing process transforms the resin into plastic, creating a rigid laminated sheet suitable for daily use in interior and exterior applications. The topmost decorative sheet provides the final aesthetic finish, mimicking natural stone, woodgrains, and more.

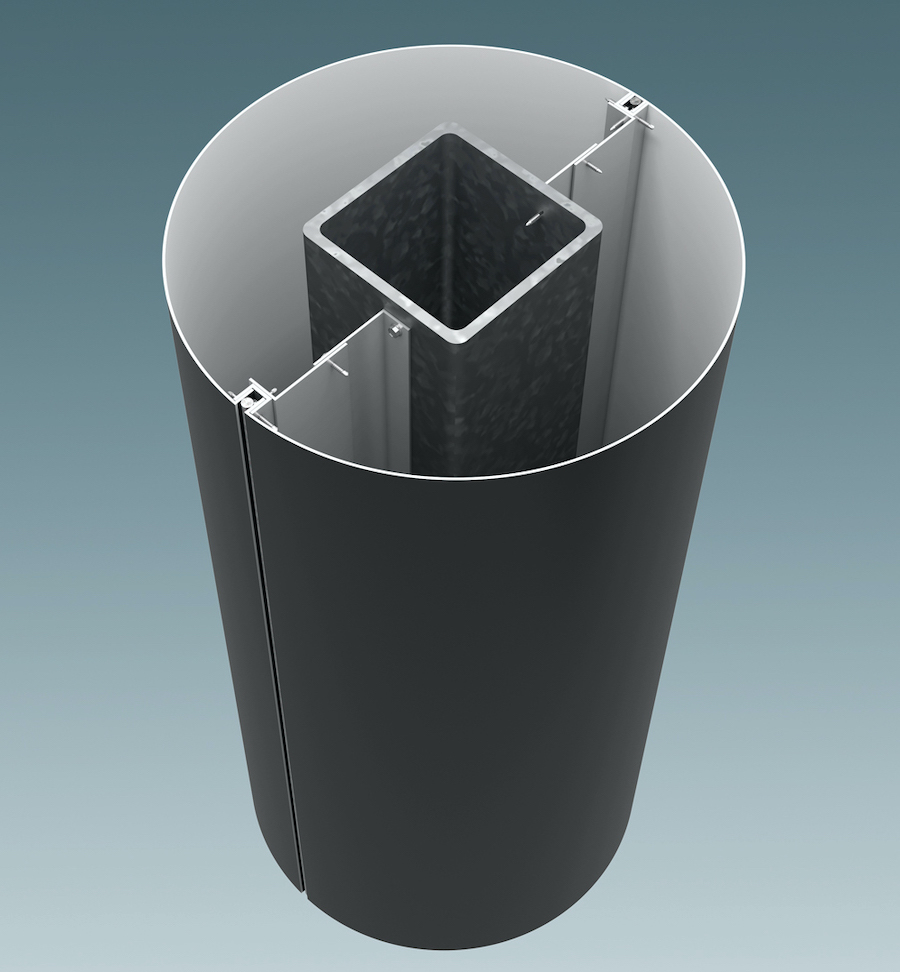

HPL panels can be applied to vertical and horizontal surfaces for general purposes, decorative facing, backing, post forming, and other speciality purposes such as cabinetry, flooring, furniture accents, and linings.

From coast to coast, CEI Materials executes complete building envelope solutions. Contact a CEI representative near you to learn more about our architectural panelling specialities and high-pressure laminate panel system options.

.png)