Understanding the Differences Between Plate and Aluminum Composite Material

Posted:

in

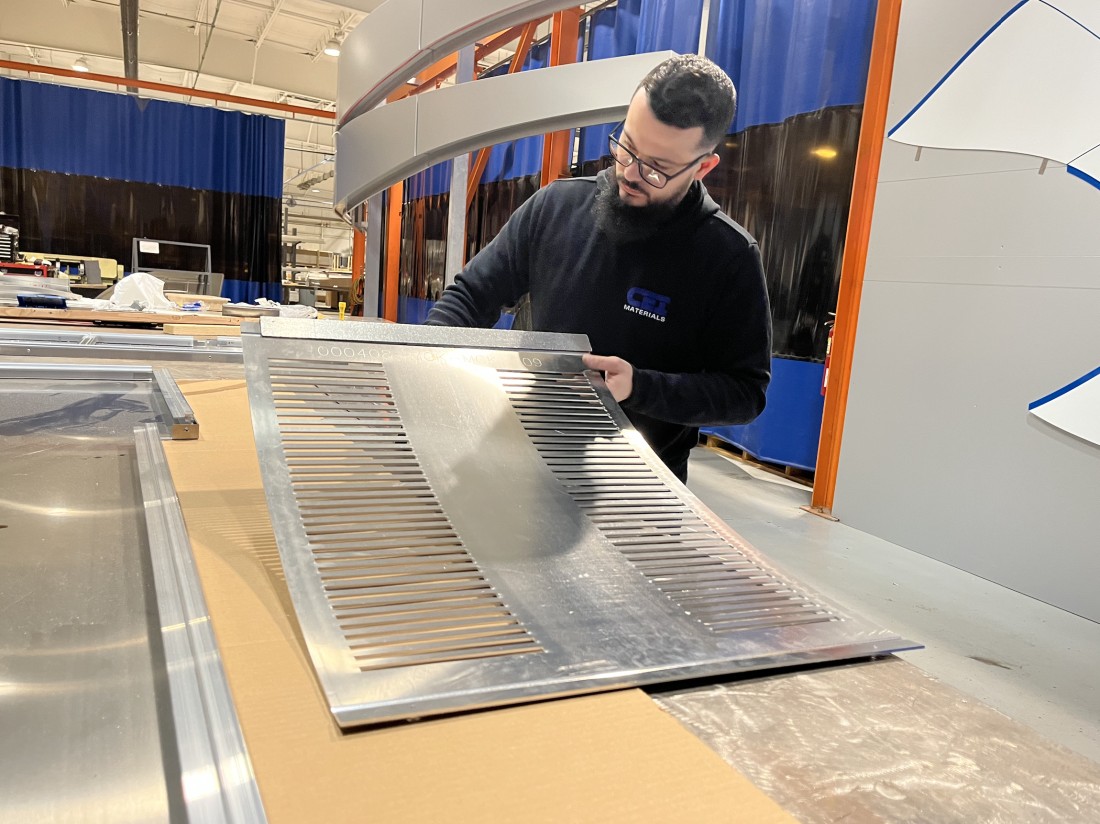

When it comes to exterior wall systems, architects and contractors have more choices than ever before. At CEI Materials, two of the most specified cladding options are Solid Metal Plate and Aluminum Composite Material (ACM/MCM). Both offer durability, design flexibility, and long-term performance—but each has unique features that make it better suited for specific project goals.

Here’s a breakdown:

Composition & Thickness

- Plate: A single, solid sheet of metal, most often aluminum but can also be stainless steel. Plate must be at least 1/8" thick to be considered plate, which ensures a flat durable surface.

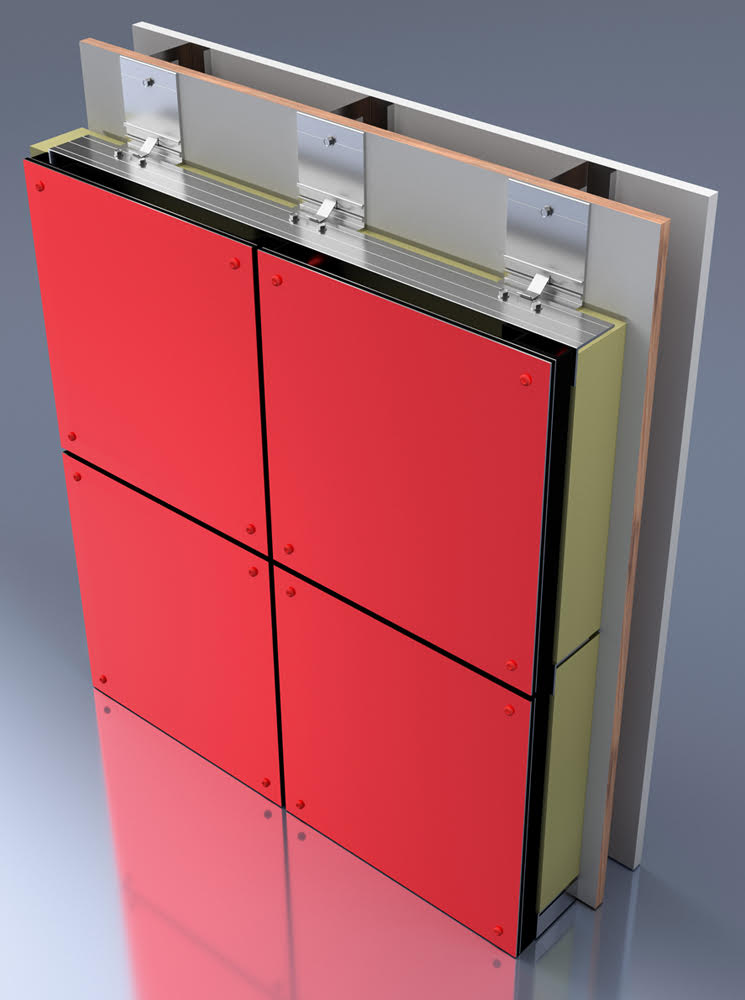

- ACM: A “sandwich” panel made of two thin aluminum sheets bonded to a thermoplastic core, such as polyethylene (PE) or a mineral-filled, fire-resistant (FR) core. These panels are typically 4mm or 6 mm thick with the aluminum skins being much thinner than the overall panel thickness.

Durability & Safety

- Plate: These panels are non-combustible and highly impact resistant due to its single-layer construction and thickness - making it ideal for high-traffic, safety-conscious environments.

- ACM: Building codes regulate the use of PE and FR cores, with performance requirements outlined in IBC Section 1406. While ACM products must meet flame spread criteria like ASTM E84, the true benchmark for safety is the multi-story fire test (NFPA 285 in the U.S. and ULC S134 in Canada). Advances in technology also minimize risks like delamination. Its lightweight nature makes it efficient for large-scale projects.

Oil Canning

- Plate: Because of its thickness and strength, solid plate is far less susceptible to oil canning than thinner metal sheets.

- ACM: These panels are highly resistant to oil canning, which is a key advantage over non-composite thin metal sheets.

Aesthetics & Fabrication

- Plate: Can be welded, cut, perforated, bent, and post-finished in a wide array of colors for seamless, custom forms with a high-end look.

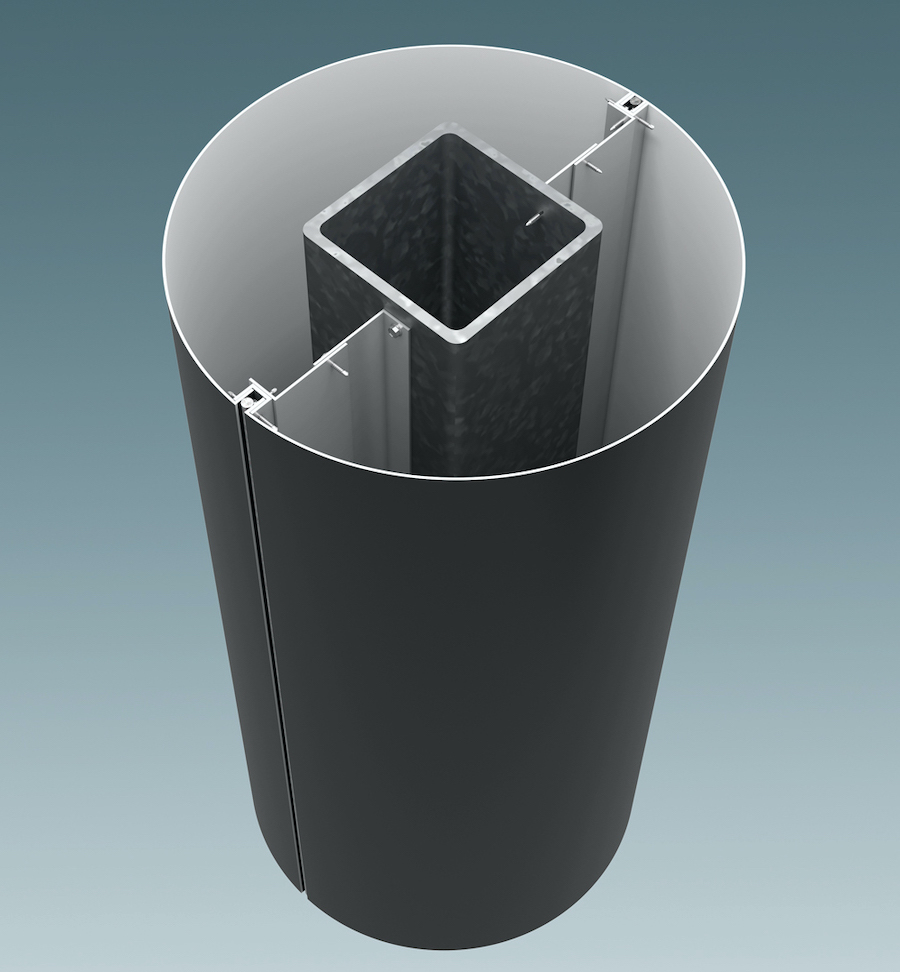

- ACM: Can be easily routed, bent, and roll-formed. Offers a wide spectrum of factory-applied finishes—metallics, woodgrains, and vibrant colors—with quick and efficient fabrication.

The Takeaway

Neither material is “better”—they’re simply different solutions for different design challenges. At CEI Materials, we fabricate both systems in-house, giving our partners the flexibility to match material choice with project vision—without compromise.

.png)